Some areas are:įull understanding of and commitment to the customer’s requirements: The time for questions on tech specs, drawings and other customer needs is before manufacturing, not after.

As a primary conduit between the customer’s requirements and the practicalities of the manufacturing process, design engineers have many opportunities to apply Six Sigma methodology to achieve better results. Let’s refocus on engineering positions now, and take a look at how Six Sigma can play a role in each. We mentioned above the extraordinary breadth of positions to which Six Sigma can be applied - which makes sense, since organization-wide buy-in is key. It’s also not an insignificant point that any training you’ve had in the past can reduce the amount that you’ll require once you’re part of a company or organization, saving them valuable training costs that can be directed to other employees or process improvements. Therefore, it’s unsurprising that Six Sigma certification or training can be a big boost to your resume. It is also likely to indicate that a person is a team player, and is unafraid to identify and improve on mistakes and inefficiencies - all great qualities to have in an employee. A Six Sigma background indicates a commitment to quality and, ultimately, the success of an organization.

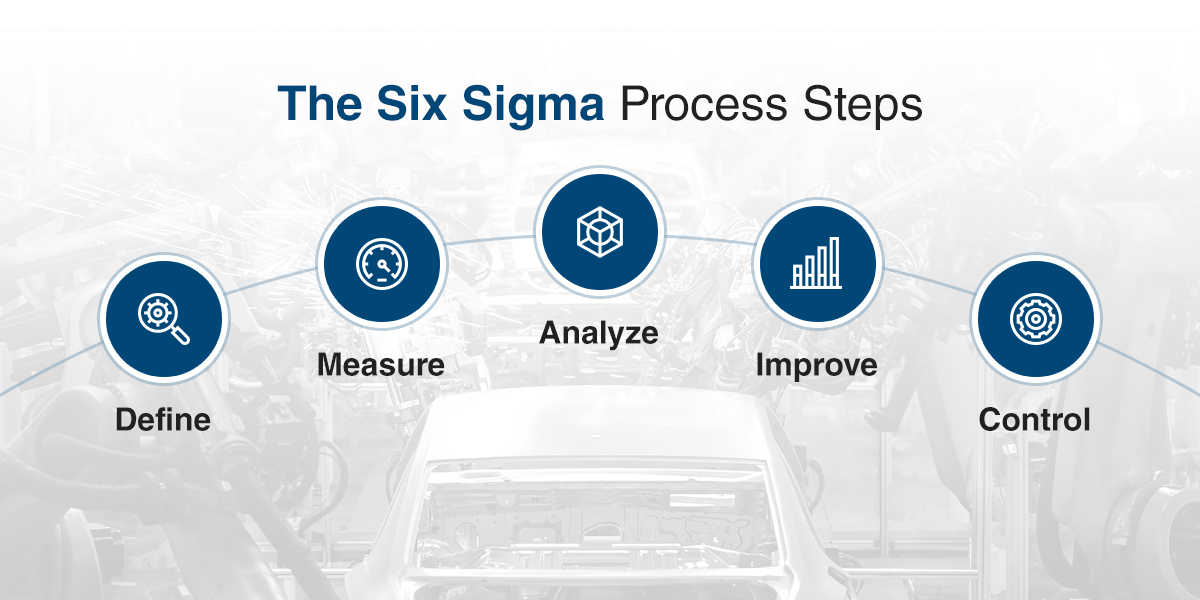

Training in Six Sigma - up to and including the highest level of Six Sigma education, the Six Sigma Black Belt - is a valuable and sought-after quality among industrial employers. Even the most siloed organization runs on the interactions between each of its members, so it’s critical for everyone to be on the same page - and working toward the same goal. Buy-in : Six Sigma doesn’t just work for a few people.Measurability : All elements of a process should be quantified, tracked, measured, reported and analyzed under Six Sigma - with the ultimate goal of improving.Predictability : A major Six Sigma goal is the elimination (or extreme reduction) of variables and instability in a process.Nowadays, it’s not surprising for project managers, website designers and administrators, and other non-industrial personnel to at least get a primer on the tenets of Six Sigma - if not a full-on training. Twenty years later from Six Sigma’s rise to popularity, all walks of employees are as likely to encounter it as any other - it’s moved beyond the shop floor and the management suite. There’s something refreshing and inspiring about a philosophy that pushes the notion of “nobody’s perfect” out the door - and which further holds that anyone, with the proper training, can achieve and contribute to that perfection. In other words, that level of production quality means that the amount and impact of defects are negligible. In the eyes of Six Sigma, perfection is, statistically speaking, possible, and is defined as fewer than 3.4 defects per million parts. Popularized by none other than Jack Welch of General Electric in the mid-1990s (although started by a Motorola engineer), the phrase “Six Sigma” has come to be synonymous with the ideal achievement of quality - which is fitting, since the methodology strives for perfection. Six Sigma holds a storied place in the recent history of manufacturing.

0 kommentar(er)

0 kommentar(er)